Nothing happened last week. No point in recounting the many reasons that steel day was postponed, but it happened today and it was quite a show. This is a story that we will tell in pictures and their captions.

sets the height of the post.

Nothing happened last week. No point in recounting the many reasons that steel day was postponed, but it happened today and it was quite a show. This is a story that we will tell in pictures and their captions.

Over the weekend, the house that we are selling on the UCI campus was tented to ensure that there are no termites. We close on the sale of this house a week from Friday.

Otherwise, not much has been happening – sigh. This may in part have been due to the weather. Friday night into Saturday it rained. Then late Sunday evening Santa Ana winds started up. These are hot, dry winds that come off the desert. The high wind warnings were for gusts up to 70 mph. This is the time of year that we pray that there will be no fires — the rain Friday certainly helped on that score — and that the power lines will stay up. In that

We did, however, manage to resolve one issue that was worrying us. After consulting with the contractor and the structural engineer, a plan was developed to deal with a “cold joint” in the concrete span of

On Wednesday, the concrete trucks came and poured all the walls that were framed for pouring. We had an appointment with the designer who is helping us with plans for the interior, so we were unable to

But Thursday was a very different story. All the wood forms were removed, so all the new

Picture 3 is the opposite side of the wall (the opening is where the front door will go), which is just the regular texture.

Picture 4 shows the west wall. Only the part on the left is new. To the left of that will be the edge of a floor-to-ceiling window that will wrap around the corner. At the left of the new section of wall, you can see the exhaust vent and air intake for the wood stove that will be there. To the right of that is the window, which will be in the dining room, that will allow in

Next week the framers will come to build the interior walls of the first floor and the floor for the second floor. Before they can floor the second floor, however, they need to install a steel beam that will support one side of the second floor. Picture 5 shows the posts for that beam and the newly installed brackets to hold the ends of it. Yesterday, the fabricator came out to make precise measurements for the beam, which should be delivered Monday.

Once the framing is in place, the concrete guys can use the second floor, instead of scaffolding, while they build the forms for the concrete for the second floor walls. They should also begin working on the rebar for the floor slab in the great room and in the garage so that they can pour those along with the final wall.

You would think that since the movers came and took everything away on Thursday, there would be nothing left to do at the Irvine house. But we spent much of Saturday and Sunday afternoon there finding stuff hidden in back corners or cabinets and trying to freecycle furniture we no longer need. Although we weren’t at the new house, the steel guys were there on Saturday. They got a lot of the rebar for the board-formed wall up.

Today on Monday, they finished the rebar on the

On Tuesday, they finished up the framing over the board-formed

I see that there have been no blog entries for almost a week. Partly this is just because the construction of concrete forms for walls is finally beginning to seem somewhat routine. Another reason that we have not been posting much is that we have been in Irvine most of this week working frantically to sort through 17 years of accumulated stuff in preparation for moving everything from our Handel house to storage. Although we packed over 100 boxes ourselves, it still required the help of crew of 3 packers all day Wednesday to finish most of the packing. Then 6 movers spent all day Thursday loading three 24′ trucks to move everything to storage. Even with all of this help Thursday was an absolutely brutal day for both of us.

A final reason that progress has been slow is that we got 0.7″ of much needed rain Wednesday night. Because rain was forecast for Wednesday and everything was wet on Thursday, little or no work happened on the construction. Picture 2 shows one of the workman removing some of the accumulated water from the plastic that is keeping the subfloor over the crawl space dry.

If we have gotten a little jaded watching the concrete forms go up, today we got to see something new since they were working on the forms for the “board-formed” wall by the front door. The concrete on the outside of this wall will be exposed and will look like it was constructed using a form made of individual boards. Picture 3 is a photo from this morning as Javi is working on that wall. Picture 4 is one taken later in the day showing the board-formed side of the wall completed.

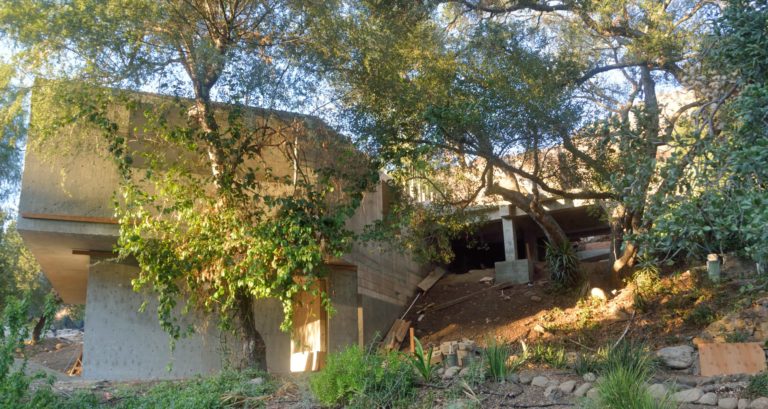

We will leave you with Picture 5 that is of the garage/apartment structure and one of the decks taken from our orchard at the base of our property.

The framers were meant to come on Friday to cover the insulation with sheathing. They showed up on Saturday, as we are under the threat of rain from hurricane Rosa. On Friday, the rain was forecast to start as early as Sunday night, but now we will be lucky to get much, if any rain, on Tuesday or Wednesday. You can see tubes of caulk, which I believe they used to seal the edges where the plywood meets the concrete. The entire crawlspace and insulation

We have been busy packing up our house in Irvine that we are selling now, even though the new house will not be done

In addition to working on the wall on the west side of the great room, they have also been putting up the forms for the wall on the east side of the great room. This is the wall that will have the front door in it. Picture 1 shows those forms from the outside; Picture 2 shows it from the inside. The inside of the plywood form for this wall will be lined with strips of heavily grained wood so that the outside of this wall will have a “board-formed” look.

Picture 3 shows the rebar that they have been putting up for the wall on the west side of the great room.

Picture 4 shows the fiberglass insulation that they installed today between the joists in the floor over the crawl space.

Finally, Picture 5 provides a bird’s eye view of the construction taken from the hillside above the house. The wall that you can see in the middle of this picture is the one on the east side of the great room.

Over the last two days they finished removing the outside forms from the walls that they poured 10 days ago, they have started putting up the rest of the forms for the first floor walls, and the plumbers have begun running the waste lines in the crawl space.

Today the framers came back and put up all the joists for the part of the house that has the crawlspace under it.

Nina was at yoga this morning when several of the neighbors told her that “a lot of lumber was delivered to

But they didn’t just get lumber delivered. Picture 3 shows that they put up all of the ledger boards for the first floor on the outside walls of the crawl space. A ledger board is a large piece of lumber — I believe that these are 4×12’s — attached to the walls with bolts embedded in the concrete wall. Once the ledger boards are up, the beams and joists can be attached to them. In Picture 3, the ledger boards are the dark lumber (since it is mounted on the concrete, it must be treated). Picture 3 also shows the first of the beams in place.

This next is for those of you who like wonky details. Picture 4 is an enlargement of the concrete pier in the foreground on the left in Picture 3. The beam is cut and there are supports and brackets supporting the beam on each side of the cut. Notice that, below the cut is a metal bracket with four bolts coming up from it. Eventually, a 4×4 steel post will be bolted to this bracket. The beam will be cut out above it to allow it to pass through. This beam will hold up one of the outside walls of the second floor