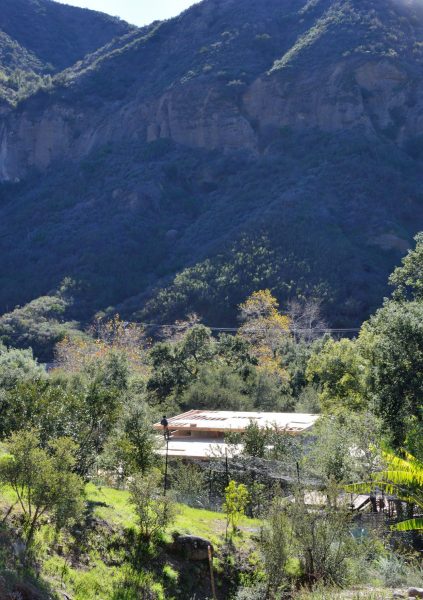

It has been a week since the last blog for a number of reasons. Now that we are living full time 45 minutes from the construction site, it is more difficult to get out there often. In addition, this week Ted was consumed with the Campuswide Honors Program admission process. Finally, it rained some last week and is raining Monday through Thursday this week. So maybe these posts will start being weekly, and maybe not …

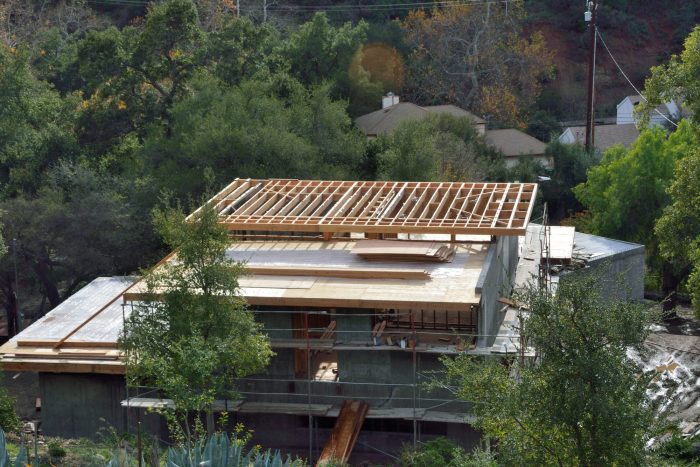

Although most of the high roof has been completed for a week, there was a section, in the southeast corner, that they never put the sheathing on. When we asked, we were told that a steel beam in that section was too short (See Picture 1) and that they needed to fix this before they could complete the roof. When Ted was out last Thursday, the steel workers were there to work on the beam. However, the big news was that the general contractor had looked at the way that the high roof had been constructed, pronounced it completely wrong, and told the framers that they needed to take off all of the sheathing and the wood strips creating the roof pitch on the high roof, and replace it. Picture 2 shows the sheathing coming off. Picture 3, taken when we were out again on Sunday afternoon shows it all off.

What was the problem? What was constructed was a “hip” roof: the high point of this roof was a ridge running in the center of the roof, so that the roof sloped from this center ridge toward all four sides. This is a common roof design that you see on many older houses. The plans, however, call for the roof to be a flat plane, higher on the south side and sloping toward the north side. Because the pitch is only on the order of 1/2″ per foot, which way it runs hardly seems like a major aesthetic issue, but the contractor was adamant that is was “wrong for the style of the house” (and it was not according to the plans). While we are happy to have the contractor making sure this is all done right, we are unhappy that a large section of the house is now open to the elements during the week when we are getting 4-5 inches of rain.

Ted was out on Thursday because Angie, a representative from Fleetwood who is manufacturing our windows, was on site to measure the window openings and consult with Kevin, our general contractor, and the subcontractor who will be actually installing the windows. They are shown looking at the plans in Picture 4. Angie was amazing, dominating the conversation with all of these

Also at the site on Thursday were electricians who were installing the can light fixtures in the ceiling. Picture 6 shows this work in progress. Picture 7, taken Sunday, shows a line of installed lights in the kitchen.

Also on Thursday, a demolition crew was on site removing a section of the retaining wall behind the house (Picture 8). This is in preparation for building the new retaining wall that will extend from the east side of the back of the house and join up with the segment of the existing wall that they will leave in place next to the shed (that will be torn down). Picture 9 shows the site of this wall.

Pete, our handy, jack of all trades,

The picture below shows a large stalk of green bananas with their flower at the end of the stalk.

These are the snowdrops coming up at the bottom of the stairway up to the front door.