News Flash: The events described below happened over a week ago. However, today Taylor and Haywood arrived in Auckland after a journey of over 30 hours from New York. They plan to spend ten days touring the North Island on their own. It will then take them another 2 days to make their way to Dunedin. I am about done with the backlog about our travels. Perhaps for the next two weeks they will take up the story. Now back to the regularly scheduled blog post.

We were curious how 1500 sheep are milked twice each day. The key is a highly automated, rotary milking shed that holds 55 sheep at once. The cows are herded from the field – very slowly, if cows walk fast they give less milk – to the intake area of the milking shed shown below.

They are funneled into stalls on what might best be characterized as a merry-go-round for cows. The cows want to get into a stall, because the machinery automatically gives them a dollop of molasses.

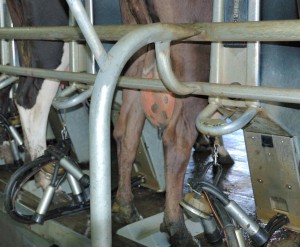

Once in the stall, the milking cups are put on their teats; this is really the only manual step in the entire process. The man shown here doing that is Gerald, the son of Graeme and Helen, who now rents the farm from them and runs it.

Once in the stall, the milking cups are put on their teats; this is really the only manual step in the entire process. The man shown here doing that is Gerald, the son of Graeme and Helen, who now rents the farm from them and runs it.

While the cow rides around, she is milked automatically.

While the cow rides around, she is milked automatically.

As soon as she is milked out, the machine detects this, the suction is removed from the cups, and they automatically drop off. This is important because leaving them on too long is a cause of mastitis.

As soon as she is milked out, the machine detects this, the suction is removed from the cups, and they automatically drop off. This is important because leaving them on too long is a cause of mastitis.

Just before the end of her ride, iodine is sprayed on each cow’s udder.

Just before the end of her ride, iodine is sprayed on each cow’s udder.

A spray of water on the cow’s front feet, signals them to back out of the stall and head off to their new field.

Each cow has an ear tag with a number and a barcode that is read as she enters the stall. This allows the computer running the machinery to track the amount of milk given by each cow. Also, if a cow is being treated for mastitis or some other problem, she will be milked but her milk will automatically be shunted aside to be discarded.

All 1500 cows can be milked in under three hours by just two people. One is responsible for attaching the milking cups. The second person herds the cattle into the sheds and also helps keep the machinery washed down since the cows do not necessary stop elimination processes while they are being milked.

The end result of this impressive process is milk in these two 1600 gallon tanks. Because it is fall here, they are starting to cut back on milk production; currently they are only sending out about 2400 gallons a day.

The end result of this impressive process is milk in these two 1600 gallon tanks. Because it is fall here, they are starting to cut back on milk production; currently they are only sending out about 2400 gallons a day.

Milking operations like this one are common here, but, I believe, rare in the states. When Taylor was at Bobolink, their cows were grass fed; however, in America this seemingly natural state of affairs is the exception rather than the rule. Instead, cows in America are larger, they are fed a feed mixture composed mostly of corn, and they confined in stalls. The result is that each cow in America gives more milk, and the milking process is far more efficient. On the downside, their feed is more expensive, and the structures that hold them are expensive to build. Because they are confined, their effluent becomes a point source of pollution rather part of the natural fertilization of the fields. Here, even the effluent from the milking operation is caught, and after a natural biodegradation process, used to fertilize the fields. Because the digestive system of cows is evolved for a high fiber grass diet, a corn based diet causes them to have digestion problems that then have to be treated. A tangible manifestation of this is that a dairy cow in America can give milk for about 5 years before she “burns out.” Grass fed cows are productive for two to three times that long.

Although it may be slightly less efficient, the grass feeding system is also more sustainable; a dairy like this one can operate for generations with little external input other than sun and rain. Feeding cows a grain diet requires corn. Growing corn in America is an energy intensive operation that makes heavy use of artificial fertilizers and herbicides. Tilling fields to grow corn leads to the loss of topsoil that was created over centuries by the prairies and forests that these fields have replaced. Clearly, feeding billions of people is a challenge and efficiency matters. To my mind the combination of sustainability and efficiency in an operation like this one makes far more sense than the combination that is dominant now in America.